Open Automation, Engineering Efficiency, & Workforce Transformation

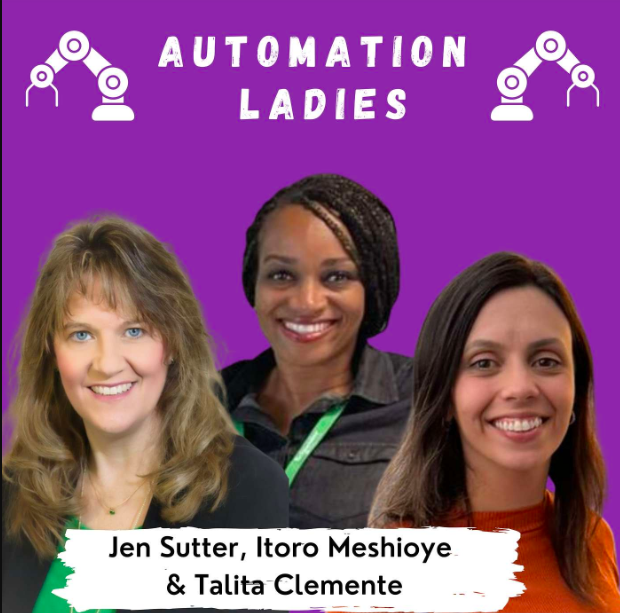

As we continue reviewing some of our older episodes, we’re reminded that truly impactful conversations don’t lose their relevance. In this session, the Automation Ladies sat down with Jen Sutter, Itoro Meshioye, and Talita Clemente from Schneider Electric to discuss a topic that continues to reshape the industrial landscape: open, flexible automation.

Even though this episode was recorded some time ago, the themes of scalability, workforce readiness, and engineering efficiency feel even more important today.

What Is EcoStruxure and Why Does It Matter?

At the center of the conversation is EcoStruxure, Schneider Electric’s IoT-enabled architecture designed to unify energy management, automation, and sustainability into one cohesive ecosystem.

The goal? Help organizations optimize operations, improve efficiency, and leverage real-time data to make smarter decisions.

Within this framework lives EcoStruxure Automation Expert, an implementation of universal automation principles built on the IEC 61499 standard. Unlike traditional systems that tightly bind software to specific hardware vendors, this approach introduces a powerful shift toward openness.

The Rise of Universal Automation

The episode dives into the mission behind the UniversalAutomation.Org, a not-for-profit organization bringing together vendors, end users, universities, and industry leaders to create a shared runtime for automation.

In simple terms:

-

Software becomes decoupled from hardware

-

Companies gain freedom to choose vendors

-

Operations become more resilient

Historically, purchasing a PLC often meant committing to a single vendor ecosystem for years. Universal automation challenges that model by enabling software portability across compatible platforms.

Think of it like moving from a locked smartphone ecosystem to something more flexible, where choice drives innovation.

Why Flexibility Is No Longer Optional

Supply chain disruptions highlighted a major weakness in traditional automation strategies: dependency.

When critical hardware wasn’t available, projects stalled, deadlines slipped, and costs climbed.

Open automation introduces optionality.

Instead of waiting months for a specific component, teams can pivot to alternative hardware without rebuilding their entire control architecture. That agility protects timelines, budgets, and customer relationships.

Engineering Efficiency in Action

One of the most compelling moments in the episode is a live demonstration showing how quickly a new pumping station could be deployed.

By leveraging reusable libraries and drag-and-drop configuration:

-

New stations can be created in minutes

-

Communication mapping is largely automated

-

HMI generation requires minimal manual setup

-

Engineering hours shrink dramatically

Beyond speed, standardization also reduces human error — a critical advantage in complex industrial environments.

As Talita notes, once your library is built, scaling becomes significantly easier.

A Tool Built for the Next Generation Workforce

Another powerful takeaway is how open automation could reshape talent development.

Traditionally, new engineers spend months shadowing senior team members just to become productive in ladder logic environments — knowledge rarely taught in universities.

Function block–based systems feel more familiar to modern engineers and even adjacent disciplines like computer science.

The result?

-

Faster onboarding

-

Shorter learning curves

-

Increased productivity

-

Broader talent pipelines

At a time when experienced professionals are retiring faster than they can be replaced, tools that accelerate readiness aren’t just helpful, they’re essential.

Making the Industry More Accessible

Open standards don’t just improve technology, they democratize it.

When platforms are vendor-agnostic:

-

Companies aren’t forced into narrow hiring pools

-

Engineers gain transferable skills

-

Organizations can attract more diverse talent

-

Innovation accelerates

Ultimately, openness fosters inclusivity across the automation ecosystem.

Training and Getting Started

For those interested in exploring the platform, Schneider Electric offers formal training resources, and the speakers encouraged professionals to connect, experiment with the software, and build familiarity early.

Because when the right business case appears, having trusted connections, and foundational knowledge, can make all the difference.

Community Still Matters

One unexpected highlight from the conversation was the reminder that relationships remain at the heart of industrial progress.

Building authentic professional connections, whether through events, demos, or social platforms, creates a trusted network engineers can rely on long after a presentation ends.

In an era increasingly shaped by AI and automation, genuine human connections are becoming more valuable, not less.

Why This Conversation Still Resonates

Revisiting this episode makes one thing clear: open automation isn’t a passing trend, it represents a structural shift in how industrial systems are designed, deployed, and scaled.

From engineering efficiency to workforce transformation, the ideas shared here continue to influence how organizations prepare for the future.

And if there’s one message worth carrying forward, it’s this:

Flexibility is no longer a competitive advantage — it’s a requirement.

If you enjoy conversations like this and want to see more deep dives into emerging automation technologies, stay connected with the Automation Ladies community for future demos, discussions, and expert insights.